Categories

- Auto Carton Packaging Machine

- Semi Auto Packaging Machine

- Printing Machine

- Rottery Wood & Die

- Paper Making Machine

- Nonwaven Fabrics

- Nonwaven Bag Making Machine

- Gum Tape Machine

- Poly Machine

- Coating Machine

- Auto Bricks Machine

- Auto Flour Mills Machine

- Auto Rice Mills Machine

- Auto Feeds Mills Machine

- Sweing Thread & Coning Machine

- Paper Cone Machine

- Electric Heating Boiler

- Coal Boiler Machine

- Fork Lift

- Water Treatment Plant

- All Kinds of Garments Accessorics Machine

Our Product

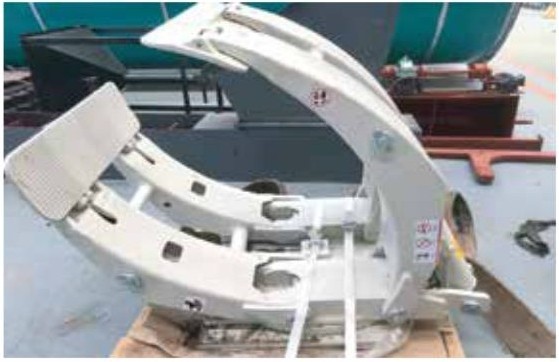

fork truck, fork hoist, and forklift truck

A forklift (also called lift truck, jitney, hi-lo, fork truck, fork hoist, and forklift truck) is a powered industrial truck used to lift and move materials over short distances. The forklift was developed in the early 20th century by various companies, including Clark, which made transmissions, and Yale & Towne Manufacturing, which made hoists.[1][2][3] Since World War II, the use and development of the forklift truck have greatly expanded worldwide.

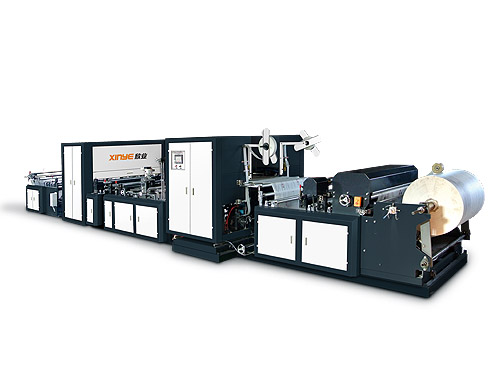

Full Automatic Nonwoven Handle Bag Making Machine With Sewing Function

MAIN TECHNICAL VARIABLES:

| Model | XY-600 |

| Power | 220V (380V) |

| Air Compressor | 0.6-0.8Mpa |

| Total Power | 13.5kw |

| Output | 10-16m/min |

| Loop Handle Bag | 20-60pcs/min |

| Loop Handle Bag | 60-110mm |

| Loop Handle Bag | 20-55mm |

| Overall Dimension(L×W×H) | 11000×2200×1950mm |

| Machine Weight | 3000kg |

Fully Automatic New Products Fabric Making Production Line Machine with CE

Our company specializes in producing Width: 1.6 m /2.4m /3.2 m wide, as well as nonwoven polypropylene bonded nonwoven production line production equipment. The use of polypropylene products for raw materials, high temperature melting, spinning into a network of adhesion of hot-rolled, cut, such as winding continuous production process.

Fully Wetback Three Pass packaged Boiler

STEAMAX is a three pass, smoke tube fully wet back boiler, which can fire solid fuels like coal, lignite and wood. The fuel is charged through a charging door to keep the fire going. STEAMAX is designed to provide low cost heating with minimum operational complexity.

FX203/FX205/FX207 FX203/FX205/FX207 Flyover Suction Deviation Correction Tensioning Device

| model | FX203/FX205/FX207 |

|---|---|

| Effective width | 1600/1800/2200/2500/2800mm |

| Fan power | 4kW/unit |

GL-213 Automatic tape making machine BOPP Gum adhesive tape slitting cutting machine

High quality bopp jumbo roll slitting rewinder machine is slitting and rewinding the bopp jumbo roll into tape in all sizes for carton packing use etc. It is suitable for the production of bopp tape, transparent tape,stationery tape, super clear tape and other adhesive products.

GM-30 double glue machine

technical parameters:

- temperature range of the preheater:160—200℃ steam pressure:8—1.2Mpa

- Air source system :0.4—0.7Mpa

High Standard Quality PP Spunbond Nonwoven Fabric Production Line, Non Woven Branded Fabric Making Machine

This machine is suitable for PP spunbond non woven fabric making. It used PP chips as raw materials input, undergoes

the process of extrusion, spinning, quenching, closure air stretching, web formation, calendaring, winding and cutting as

per requirements and then packed for storage and delivery.